Figured I'd post a separate thread in hopes of getting the most feedback;

I'd like to make some progress this week and I'm driving myself mad trying to decide what to do about the JTR transmission cross member. I'm stealing a picture from one of Braap's build threads (Brian's 325i build) to illustrate the "hangers" that are incorporated in JTR's design. These require drilling four holes in the trans tunnel, which I'm reluctant to do for various reasons.

I guess I can see why JTR opted for this design. With all of the pieces slotted and bolted together, there is quite a bit of adjustability. It also appears there was a deliberate attempt to keep as much space available for the drivers side exhaust pipe, as illustrated by the purple line in the green circle. And I also think it was deliberate to keep the vertical part of the bracket (orange line) further forward because the floor pan/trans tunnel "kicks" inward just aft of that position (red arrow). Keeping that vertical support forward of the red arrow keeps more space available for the exhaust.

All of that said, I'm consider eliminating the hangers and welding the remaining bits together. Or even having a different mount fabricated, like Bimerok's Version 2.0 seen here.

Once the JTR pieces are welded together, most of the adjustability will be eliminated. Right now, as I have things mocked-up, it appears the output shaft of the transmission is approximately 1/2" to 1" toward the passenger side of the car. What I'm questioning is whether this is normal and acceptable or if I need to try to adjust the motor mounts, if possible, to get the center of the output shaft perfectly centered in the tunnel? I wouldn't want to have this cross member welded together or have another fabbed until I'm completely sure the transmission (and engine) are positioned well enough. And that's part of the reason I'm reluctant to drill four holes in the trans tunnel. If things have to move, the tunnel starts to get hacked up drilling additional holes.

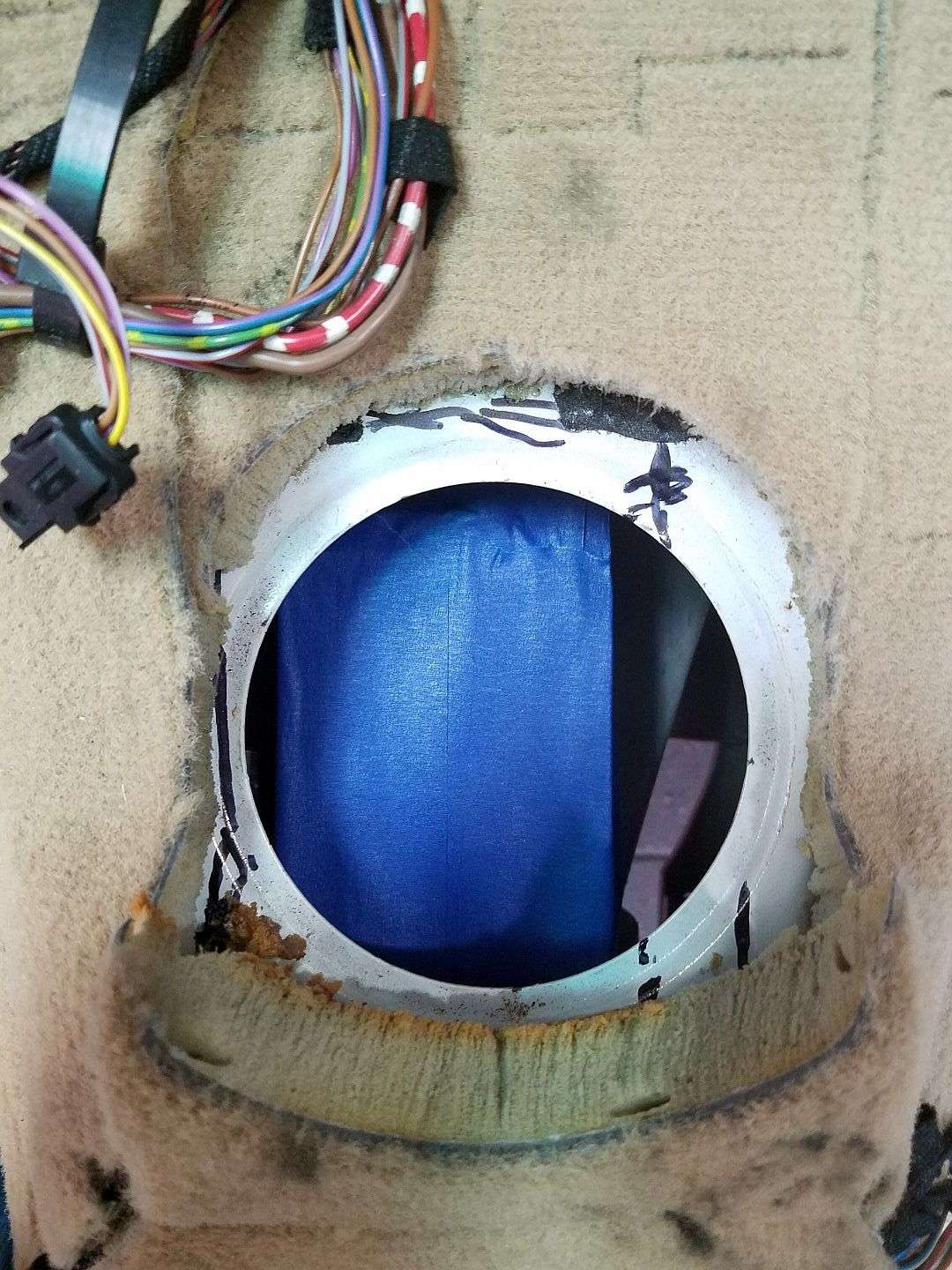

The red lines in the second picture illustrate where I'm considering cutting. The area of the black X's would be eliminated.

Any thoughts and feedback are greatly appreciated.

Tipsy

Last edited by TipsyMcStagger; 02-21-2017 at 12:24 PM.

Also, with the trans positioned as it is (tail shaft centerline slightly to the passengers side of the car), the shifter position is actually offset to the drivers side. As you can see, I've yet to enlarge the shifter opening.

How does this compare with others?

Tipsy

The T56 transmission mount is rearward of the original BMW crossmember.

Without the rear hangers, the T56 puts a cantilever load on BMW sheet metal, which will cause metal fatigue on the BMW sheet metal.

After you install the engine/transmission and the crossmember (without the rear hangers), push up and down the rear of the transmission and see how much movement you get. It should scare you.

It should scare you so much, that you will quit trying to find a way out of installing the rear hangers.

Output Shaft.

The stock BMW E36 engine/transmission is offset towards the passenger's side by about 3/4".

The stock BMW differential input flange is offset towards toward the passenger's side by about 3/4".

The JTR mounting kit maintains this offset for a number of reasons, including driveshaft alignment.

Last edited by MikeJTR; 02-21-2017 at 03:42 PM.

Thanks Mike. I had a feeling my post would draw you out of lurk-mode. With regard to the offset, I know the stock engine is offset to the passenger side. My concern is whether I have properly duplicated your intended offset with the LSx/T56. Given that the engine mounts have sliders and the fact that my frame mount position might not be 100% exactly where yours were when you prototyped/developed the kit, I'm questioning whether things fell into position where intended. The fact that the mounts CAN be adjusted has me wondering if they need to BE adjusted.

Maybe others have a perfected a better system but every time I have to remove and install the engine, I have to remove the engine mounts from the block. I really don't know if they're going back in the same position each time. Once I get a bolt through the mount, "it is where it is." I've also found I need to remove the mounts (one at a time) on each side to remove and install the headers. Again, without previous experience as a benchmark, I'm never certain things are aligned as intended, other than the fact that the engine is simply "in place."

Insofar as the hangers, I know you designed it that way for a reason. Given the rearward load, I'm surprised you didn't take advantage of all three mounting holes on each frame rail. Obviously, you didn't think this was necessary or adequate. I know if I'm looking at alternatives, you will continue to see your design to be the best option, and I respect that. But there's more than one way to (successfully) skin a cat and I'm still leery of drilling through the tunnel.

Thanks for the feedback.

Tipsy

Last edited by TipsyMcStagger; 02-21-2017 at 08:22 PM.

Bookmarks