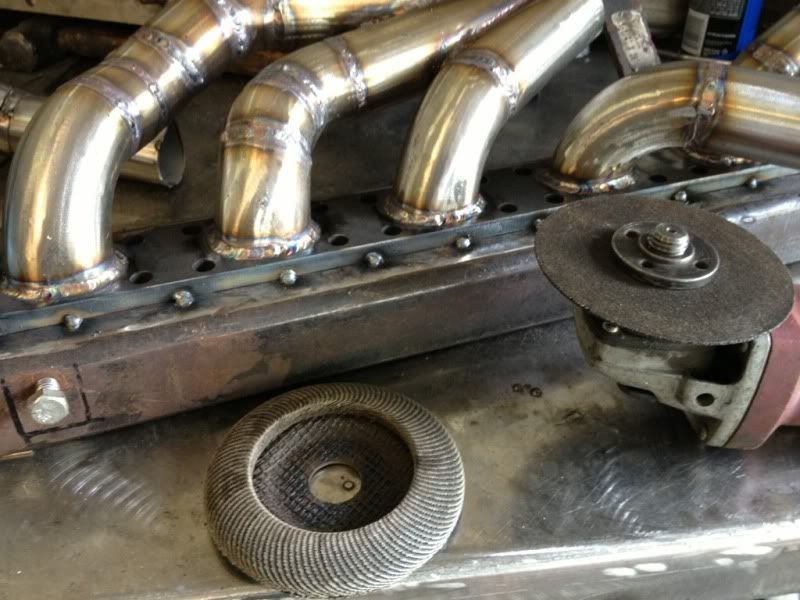

All the runners are welded to the head flange, wait for it to completely cool off to avoid warping then cut the tacks off with a cutting wheel.

I cannot stress this enough to everyone reading, wear face protection when using a cutoff wheel and long sleeves, I've seen accidents with wheels blowing up and causing lacerations to the face and body.

My manifolds powering 8sec and over 1000rwp cars

Home of the highest HP stock M30 in the world 550rwhp/622rwtq

1/4 mile---> 9.81 @138 C4 Auto

10.08 in car vid --->https://youtu.be/OiinFhUomjg

Dyno vid... http://www.youtube.com/watch?v=C7aM7..._order&list=UL

$1200 would be my limit for now and pretty sure it will be something used.

Ive heard that mainly stick to Miller but yea.

i would like to ultimately be able to weld manifolds, intercooler pipes, downpipes, and roll cages/reinforcements to the car. (i know it sounds kinda far fetched for a noob but would like this to be a life lesson kind of thing + its a good talent to know)

Do you heat before squeezing or just squeeze.Originally Posted by good & tight

PT6262 - SPA Mani- NickG Tuning - TiAl - CES Cut-Ring - Blood Sweat & Tears

PT6262 Budget Build!! | CES Cut-Ring Install Thread

Have any of the welders among you used an aluminum spool gun on a mig? Any comments? The prices look appealing compared to an AC/DC tig.

It's not a vendor vs vendor s fest because G&T isn't a vendor and the fact that he mockingly told AR Design that he should "Play nice now or you will see your's on ebay for less than 1/2 of what you charge" is rather inappropriate and shows G&T's intentions. I can't say I am terribly impressed with Otis for knocking off the design but alleging to take it to China for a fraction of the cost is plainly cutting into AR Designs livelihood - I know AR Design has a job and needs to bring money home, and to read that is just sad. In a time when local business couldn't be more important and production in the US is dying, here we have a forum member (not a vendor, btw) waving the fact that he's sending the ripped-off design overseas for production... that's probably the lowest of the low.

Spool guns are great for light weight stuff - sheet metal, etc. The problem is you need a ton of amperage if you intend to weld anything of any real thickness. It's not very appealing compared to TIG and it doesn't yield the same kind of penetration. Mishimoto rads are spool gunned - they work, but the welds on the rads are the #1 complaint against the product. Also, low end MIG machines don't support spool guns, so you need to find yourself a decent MIG with good power which means you're spending $750 - $1200 for a MIG. Without much more, you're in a TIG.

Last edited by 5mall5nail5; 10-14-2012 at 05:44 PM.

Last edited by GG///M3; 10-14-2012 at 05:49 PM.

“If liberty means anything at all, it means the right to tell people what they do not want to hear.”

― George Orwell

Did he actually mean he would send them overseas? I think he was just picking at the fact that manifolds have been copied and sold (think OBX).

I don't think he personally meant he would do it.

Continue on with tips. I would like to get a cheap TIG too.

For those of us looking for ones on Craigslist, what are some good used MIGs and TIGs to look for?

Im not disagreeing with what you are saying. Id never buy from otis after reading what he said. But we should just keep this thread full of fabrication pictures/information.

We need a fabrication section. I really want to learn to TIG weld. I might take a few classes while im up here at school, if they are offered.

PT6262 - SPA Mani- NickG Tuning - TiAl - CES Cut-Ring - Blood Sweat & Tears

PT6262 Budget Build!! | CES Cut-Ring Install Thread

If it weren't for that I'd have disregarded it, but knowing that Otis did that, it's a little... I don't even know.

Re: craigslist welder - perfectly fine if the unit is perfectly fine. You can pick one up but I have noticed that with the economy being what it is you will see guys selling a Synchro 200 for like 85-90% of new price. Problem with that is it could work fine and then not... and no warranty. But, that's just like anything else.

There's also the classified section of some welding forums. If you do guy with a Miller or Lincoln the nice thing is you can take it in to your AirGas store and have it serviced.

The guy who does the welding for Driven Innovations has an old school huge transformer machine. The key is, transformer machines are big (Miller Synchrowave, etc.) and inverter machines are small (Diversion, Dynasty). "Good" is relative. You need to identify what you will work on and then find a machine that will output that.

Do you need 110v or 220v? Some machines work only on one and some on both. Do you need AC and DC? Just DC? Do you want HF start or are you ok with scratch start? Etc.

Yes we all want to learn, but I choose to dislike people who rob/cheat/steal. There was no need for you to state do you ever stop.

Back to the topic. I'm looking into taking welding classes soon. Great thread besides the said non-vendor robbing vendors designs, and threats of sending it to China for mass production/profit.

“If liberty means anything at all, it means the right to tell people what they do not want to hear.”

― George Orwell

I would buy a little mig now, like a Lincoln 135 and a tig later. Mig is easiest to learn with. I have a little Lincoln 100 and would like to get a tig (probably one of the new inverter styles that go for about $1300). The little migs cost about $500, less if used. Sticking with a name brand so it can be repaired is the smart route. Many of the chinese welders are attractively priced, but like cheap chinese generators, become paper weights when they break.

I have a chop saw (abrasive) and a band saw. With the little mig, I can cut and tack weld stuff and then take it to a pro for full welding. Mod Addict and I made an entire 3.5 inch exhaust for his car.

Last edited by pbonsalb; 10-14-2012 at 07:08 PM.

what do you guys think as a beginners tig welder?

http://www.eastwood.com/tig-welders-...FYaDQgodLXEAmA

Just squeeze, like I had mentioned early get a good table vice.

And for the record I do not intend to make copies in china from it. Two of my own designed manifolds have been sent and copied and would certainly not do it to someone else. I'm not fond of this manifold design, but I will keep my comments to myself.

Back to the topic on hand:

Manifold removed from jig, here's a peak inside the exhaust port. Very minimal die grinding needed to make a nice smooth entry.

Turbo flanged mounted, just need to add the wastegate ports, dual v-band 38mm.

My manifolds powering 8sec and over 1000rwp cars

Home of the highest HP stock M30 in the world 550rwhp/622rwtq

1/4 mile---> 9.81 @138 C4 Auto

10.08 in car vid --->https://youtu.be/OiinFhUomjg

Dyno vid... http://www.youtube.com/watch?v=C7aM7..._order&list=UL

The price of the Eastwood stuff is tempting and there is probably better quality control than some of the other Chinese tigs, but what do you do after 3 years if something breaks? Or 5 or 10 years? With a Miller or Lincoln, it can be fixed.

When it first came out, I think Eastwood was selling the tig with the plasma cutter for $1000.

Bookmarks